In Stock

Product Description

Highlights:

- Gains of 21BHP

- Increase of 28NM of torque

- 27% more volume over OEM

- Bar and plate design

- Designed and manufactured in the UK

- Lifetime warranty

Following the success of our performance enhancing products for the Hyundai MK3 i30N and Veloster N, it was only obvious we should further develop on another of Hyundai’s popular performance N platforms, the Hyundai Kona N. Due to the difference in crash bar design, and following intensive testing, we found that, unlike the i30N, a stepped core was not the best performing intercooler during testing, neither would it offer to be a completely reversible plug and play solution.

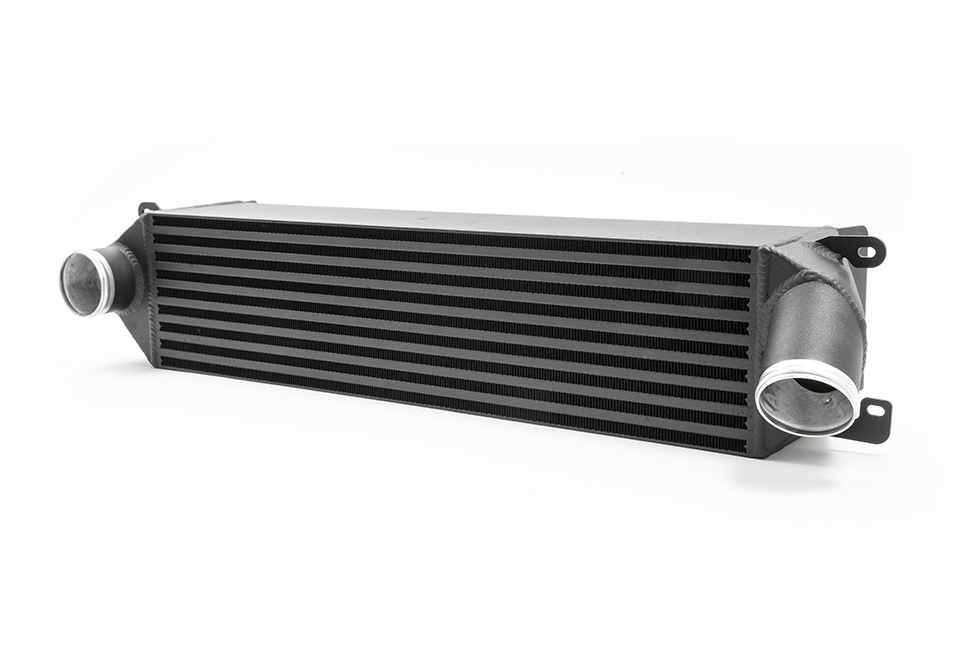

In the development stages, our engineers used their knowledge and sheet metal expertise to help improve vital airflow through the bar and plate core by hand forming alloy sheet metal and the necessary brackets to mount the 83% larger volume intercooler in the OE position. This is the ideal location with a frontal surface area increase of over 27%, and has no detriment to any other of the vehicles cooling components. The development team also created a hand fabricated ducting system that has been skilfully integrated into this superior design, to ensure as much air as possible passes through the face of the intercooler.

The inlet and outlet sizes have been increased in diameter to 65mm, giving an increase of 27% more volume over the intercooler OEM boost tract to give improved flow. The development team also added a custom hard pipe, increasing the diameter to 64mm, up from the factory 50mm. This replaces the stock factory pipe on the hot side to ensure this package gives you all you need for maximum performance gains on high levels of tune.

The boost pipe and intercooler come in our standard black textured finish powder coat for maximum longevity. If you are looking to enhance this performance package, we would recommend adding our cold side boost pipe FMBP7 to achieve an even more elevated performance experience.

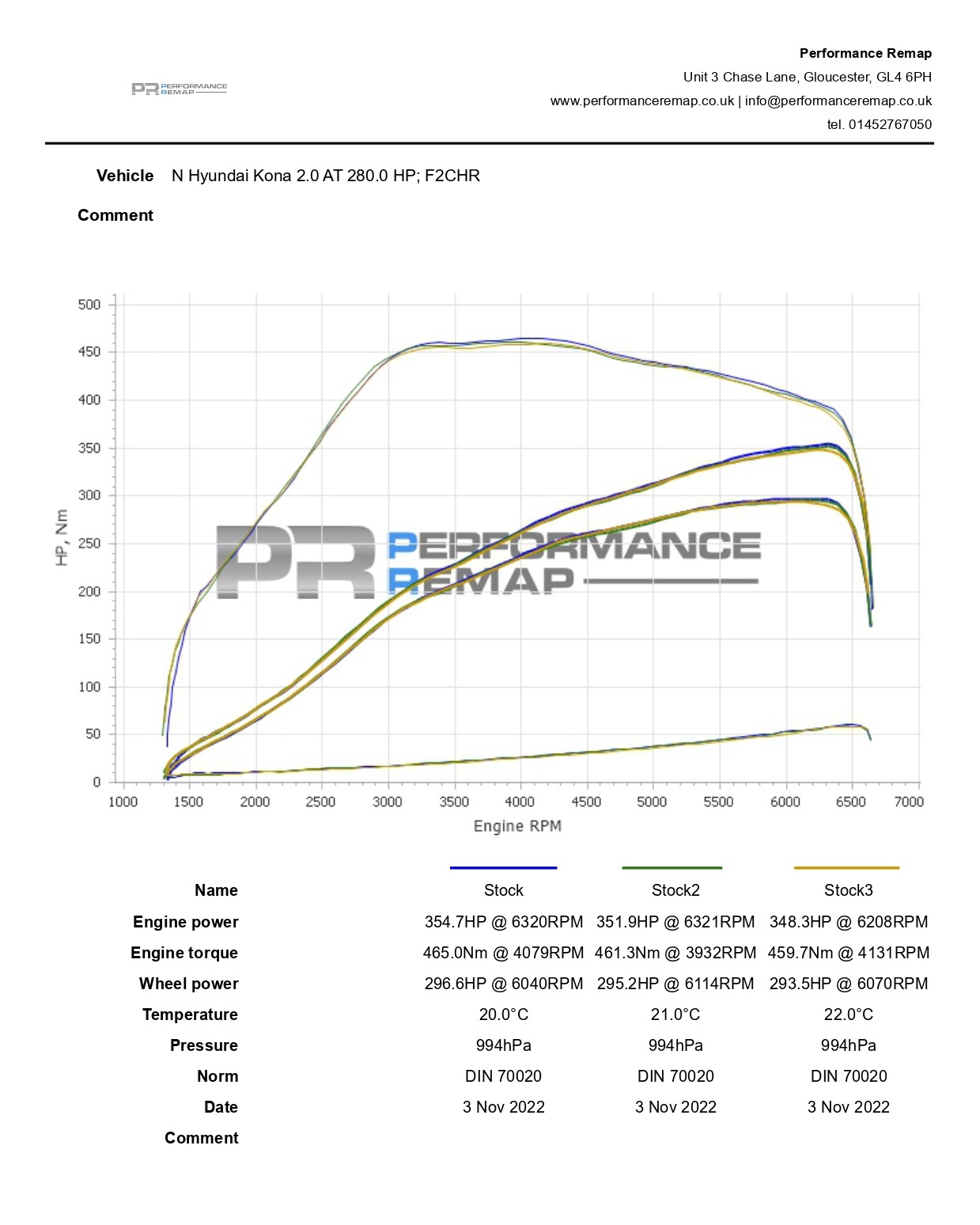

Dyno Testing

With Hyundai using the MK3.5 i30N engine, and them re-developing the turbo charger to run more boost with a larger flow than the previous generation, there is even more reason to replace this restrictive OEM intercooler with the larger Forge Motorsport item.

The development vehicle used for this product already had a stage 1 ECU calibration from Courtney Sport, and was fitted with the Forge Motorsport intake (FMINDK28) and turbo inlet adaptor (FMTIA10). The results below show the vehicles power output before the Forge Motorsport intercooler was installed, using the OEM item the results were still impressive, however after a few pulls the tuned engine did start to struggle keeping the inlet air temperatures low.

During our extensive testing, we let the car heat soak on the dyno until the radiator fans tripped on and off (which gives an inlet temperature of around 40°C), we then did a dyno pull from this point. In doing this, it gives a more consistent result and reflects real-world driving conditions more accurately.

Testing was completed using Performance Remap in Gloucester with their VTEC 4-wheel drive dynamometer, this was to ensure all our data has been achieved with results as accurately as possible by an independent tuner. As you can see on the third run, as the inlet air temperature starts to rise, BHP output was measured at 348.3HP with 459 NM of engine torque.

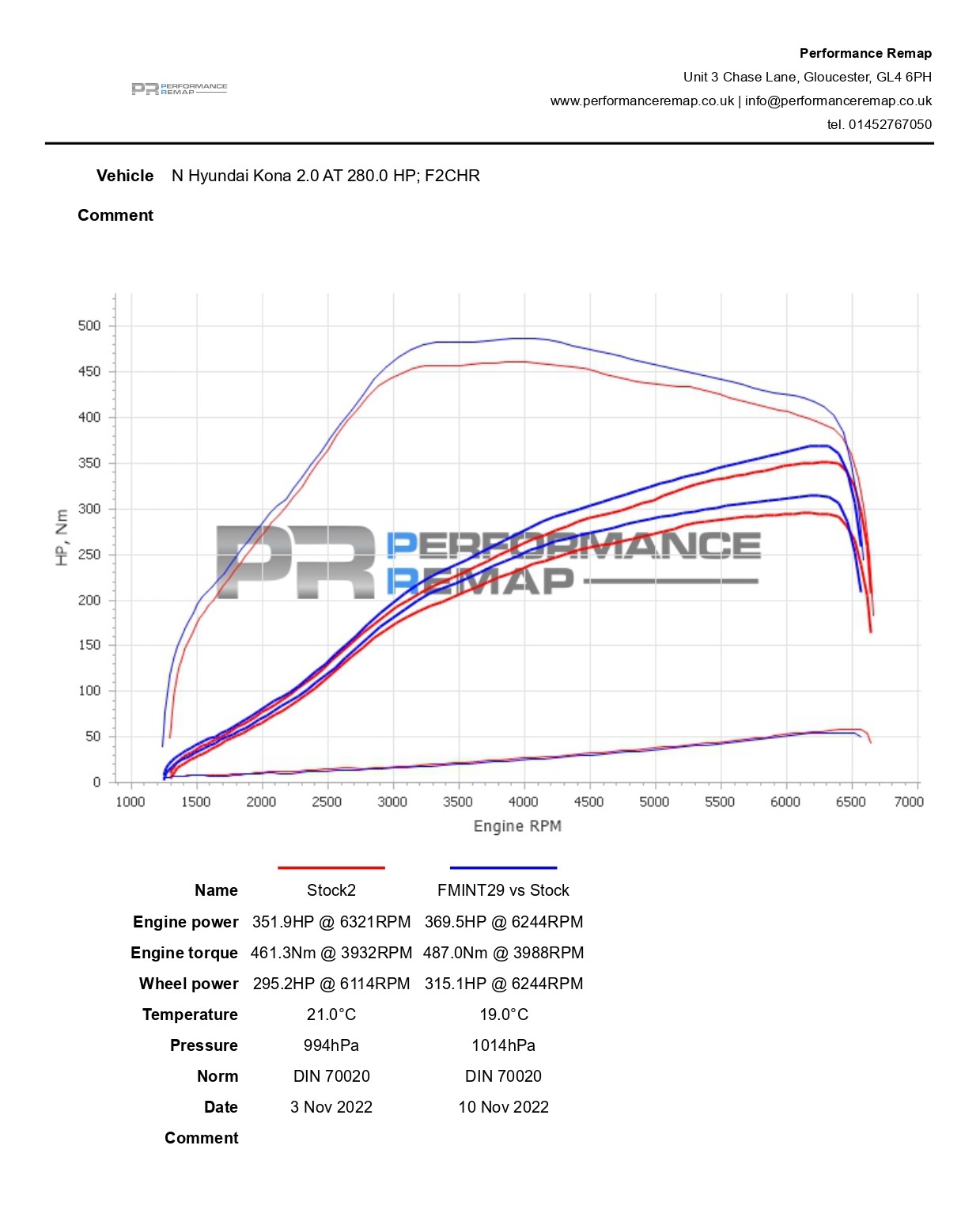

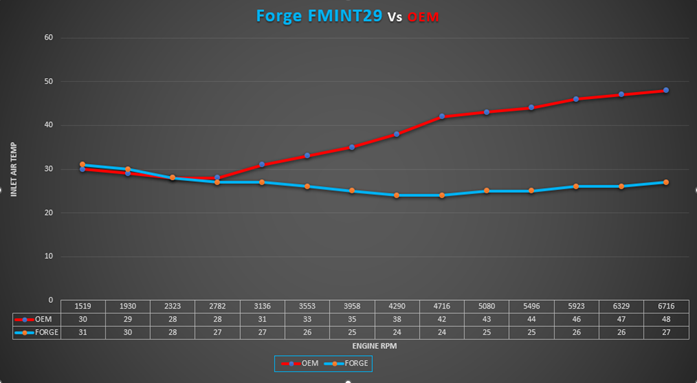

The new addition of the Forge Motorsport intercooler made a huge difference to the vehicles power output and continued to keep the inlet air temps at around 27°C, with gains of 21 BHP and 28 NM of torque at peak, along with a significant increase from 3000 RPM, the performance gains can be felt when driving this vehicle.

After more than six pulls on the dyno, we still had safe IATs, and the Forge Motorsport intercooler gave results of 27°C, nearly halving the factory’s intercooler intake temps from 48°C. These tests took place in relatively cold conditions, with an ambient dyno cell temperature of 20°C, proving how inefficient the stock intercooler is. In the summer months, the stock intercooler along with higher inlet air temperatures will have a hugely negative impact on the engine’s performance. In these conditions, the engine management will retard the ignition, resulting in a lower powered engine as temperatures rise and the ECU then pulls out the timing to stop detonation. On a mapped vehicle, the results will be even more detrimental and can lead to possible premature engine wear.

This intercooler combined with our intake, and a quality aftermarket cat back exhaust with factory software will deliver you unparalleled levels of performance.

The Forge Motorsport front mount intercooler has all the necessary hardware to install the kit in approximately 3 hours depending on competency and tools available.